TORQUE CONVERTER REPAIR EQUIPMENT

Hydra-Torque torque converter equipment line has been supplied to various locations in the world and provides professional quality level to any Automatic Transmission rebuilders - from family-size shops to large remanufacturers. The Hydra-Torque range of torque converter reman machines has been developed to guarantee fair combination of quality, decent pricing, reliability - all topped up by advanced training, if needed, and outstanding technical service.

The Hydra-Torque equipment line is comprised of specialized durable stands that are required for top-class repairs of Torque Converters. The original builds cover all of the standard demands by Transmission specialists but also they can be tailored upon Clients' specific requests.

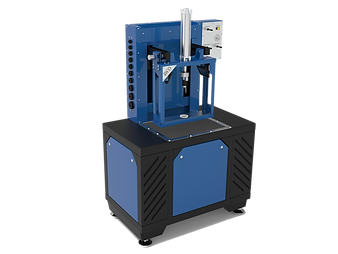

Torque converter rebuilding equipment

This torque converter welding machine is designed and adjusted in accordance with all the nuances, which may occur during the welding halves of a torque converter serving as a key in solving TC Problems. Various modes are offered to suit Customers' volumes and preferences: the unit combines TIG and MIG welding.

The Hydra-Torque piston bonder comes with a set of adapter plates covering an extensive range of transmission models. The bonder adapter plates are made of steel which makes it simple to produce additional adapters when required

The balancer is used for checking the outer shell of a Torque Converters on the subject of uneven weight distribution. Just imagine an unbalanced Converter inside an Automatic Transmission and the harm it may do when rotating at high RPM values and you will understand its use. Car services implement these tools to avoid any disagreements with their Customers and ensure high-class remanufacture, though many rebuilders tend to rely on their expertise and produce quality results without them.

Additional tools for torque converter rebuilding

Internal clearance check stand

Also known as end-play gauge stand, this tool gained popularity thanks to simplicity and efficiency. The dial gauge indicates how the internal elements of a Torque Converter are positioned within the housing. A large clearance will lead to throbbing, while a small one will result in redundant stiffness. In both instances, there will be a negative impact on the general transmission performance. This compact tool plays a key role in avoiding such situations.

Torque converter leak tester

The mechanism of compressed-air supply employed in the stand facilitates detection of leaks in a rebuilt converter unit. If a welding seam was done badly and there are leaks in a rebuilt converter unit, air pumped into the TC submerged into water will show air bubbles pinpointing the location, so even tiny gaps will be revealed. Such testing method is both effective and visually compelling.

After the air-test check the converter unit undergoing rebuilding is subsequently integrity-confirmed or is subject to additional welding, which is regularly easy to complete manually.

ZF captive clutch tool

This tool is intended for measuring the preload force of the torque converter friction clutch, thereby allowing transmission specialists to recondition ZF 6HP Converters that utilize this advanced technology. This testing device has become a real best-seller on the market and found its rightful place in equipment lines of many long-established repair shops.

HEAVY DUTY TORQUE CONVERTER REPAIR LINE

The range of HEAVY DUTY TC repair machines now available:

-

HD Torque Converter welding stand

-

HD Torque Converter balancing machine

-

HD Torque Converter internal clearance check stand

-

Lifting assist device for HD Torque Converters

The ready designs can be reviewed and adopted to the specific requirements of the Client, including:

-

simultaneous welding with 2 torches

-

robotic arm positioning, and more

Heavy Duty Torque converter welder

Heavy Duty Torque converter balancer

HEAVY DUTY CUSTOM TRANSMISSION EQUIPMENT

Do you service and repair transmissions for on and off highway equipment, forklifts, or industrial equipment? At Hydra-Test, we are transmission testing experts. We can develop a custom test system for these types of applications to your specifications so you can have confidence in your rebuild process and the products you supply to your customers. Contact us today with your testing requirements and let us quote you a solution for success.

HEAVY DUTY

722.6 Mercedes torque converter looks small on heavy duty TC welder

Torque converter Internal clearance check stand assembly process before colour application

HEAVY DUTY CUSTOM TC REPAIR EQUIPMENT

With a variety of technical requirements and specific demands, the Hydra-Test team is fully ready to take on tasks that require custom-tailored solutions. The Heavy Duty Torque Converter line has been designed not by mere scaling of the standard equipment but by means of conceptual redesign and implementation of new ideas.